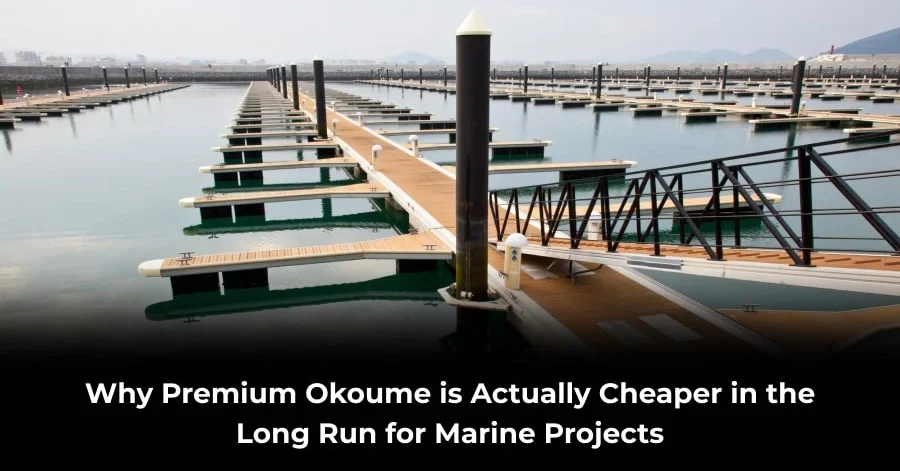

When planning a marine project whether it’s a fishing boat, luxury yacht interior, dock structure, or coastal construction many buyers focus on the initial cost of materials. At first glance, premium Okoume Plywood may seem more expensive than generic marine boards. But seasoned boat builders, naval architects, and marine contractors know a critical truth: premium Okoume saves money over time.

From durability and weight efficiency to reduced maintenance and longer lifespan, Okoume Marine Plywood consistently delivers better long-term value. In this blog, we’ll break down why investing in premium Okoume is a financially smart decision, especially for demanding marine environments.

Understanding Okoume: More Than Just Marine Plywood

Okoume Marine Plywood is manufactured from the Okoume hardwood species, native to Central and West Africa. Known for its fine grain, lightweight nature, and exceptional resistance to moisture, Okoume has become the preferred choice for high-performance marine projects.

Unlike low-grade marine boards, premium Okoume is engineered with:

- Waterproof phenolic resins

- Uniform veneer layers

- Minimal core gaps

- Superior bonding strength

This level of precision is why professional Okoume Marine Plywood Suppliers emphasize grade consistency and certification.

The Hidden Costs of Cheap Marine Plywood

Low-cost marine plywood often comes with hidden long-term expenses that many buyers overlook:

- Frequent repairs due to delamination

- Structural weakness under load

- Faster water absorption

- Higher repainting and sealing costs

- Reduced safety and reliability

What appears “cheaper” upfront often results in higher lifetime expenses, especially in saltwater conditions.

1. Longer Lifespan Means Fewer Replacements

Premium Okoume Plywood is designed to withstand years of exposure to moisture, humidity, and temperature changes. When properly sealed, it can last decades without structural failure.

Cheaper plywood may require partial or full replacement within a few years. Over time, repeated material purchases, labor, and downtime far exceed the cost of premium Okoume.

Bottom line: One high-quality installation is cheaper than multiple low-grade replacements.

2. Lightweight Strength Reduces Structural Costs

One of the biggest advantages of Okoume Marine Plywood is its exceptional strength-to-weight ratio.

Why this matters:

- Lighter boats require less fuel

- Reduced engine stress

- Improved speed and handling

- Lower transportation and installation costs

Heavier alternatives increase operational costs year after year. Builders sourcing from experienced Hardwood Timber Suppliers often recommend Okoume specifically for performance-based marine projects.

3. Superior Resistance to Moisture and Rot

Marine environments are unforgiving. Constant exposure to water can destroy poorly bonded plywood from the inside out.

Premium Okoume Plywood offers:

- Strong resistance to fungal growth

- Excellent water resistance when sealed

- Stable structure in humid climates

This significantly reduces ongoing expenses related to rot treatment, patchwork, or emergency repairs.

4. Reduced Maintenance Saves Time and Money

Maintenance is one of the largest recurring costs in marine projects. Inferior plywood requires:

- Frequent sealing

- Repainting

- Crack repairs

- Structural reinforcement

Premium Okoume surfaces are smoother, more uniform, and easier to coat. This means:

- Faster finishing time

- Longer intervals between maintenance cycles

- Lower labor costs

For professionals sourcing materials from a trusted woodworking supplies store, Okoume is often the most economical choice over a project’s lifespan.

5. Better Finish, Less Material Waste

Cheap plywood often contains core voids and uneven veneers, leading to:

- Wasted sheets

- Poor surface finish

Extra filling and sanding

High-grade Okoume Marine Plywood provides a flawless surface ideal for varnish, laminate, or paint reducing finishing materials and labor hours.

Less waste = lower overall project cost.

6. Safety and Structural Reliability

Marine safety is non-negotiable. Structural failure due to substandard plywood can result in:

- Expensive liability

- Project delays

- Safety hazards

Premium Okoume sourced from reliable Okoume Marine Plywood Suppliers undergoes stringent quality checks, ensuring dependable performance even under stress.

7. Long-Term ROI for Commercial Marine Projects

For commercial boats, ferries, or marine infrastructure, premium materials directly impact profitability. Reduced fuel consumption, lower maintenance downtime, and longer service life all contribute to higher return on investment (ROI).

This is why professional builders working with leading Hardwood Timber Suppliers consistently choose Okoume for marine-grade applications.

Environmental and Sustainability Benefits

High-quality Okoume plywood is often sourced from responsibly managed forests and manufactured with efficient veneer usage. Fewer replacements mean:

- Less wood consumption

- Reduced waste

- Lower environmental footprint

Sustainability is not just ethical it’s economical.

Why Trusted Suppliers Matter

Not all Okoume plywood is equal. Working with reputable Okoume Marine Plywood Suppliers ensures:

- Authentic marine-grade standards

- Proper certification

- Consistent veneer quality

- Reliable supply chain

Purchasing from a professional woodworking supplies store also provides expert guidance, helping buyers select the right grade for their specific marine application.

About AEW Woods

When it comes to premium marine plywood, AEW Woods stands out as a trusted name in the industry. AEW Woods specializes in high-quality Okoume Plywood, catering to boat builders, marine contractors, and woodworking professionals worldwide.

With a strong focus on quality control, ethical sourcing, and customer satisfaction, AEW Woods partners with experienced Hardwood Timber Suppliers to deliver reliable, marine-grade solutions that perform exceptionally over time.

Conclusion: Premium Okoume Is a Smart Investment

While premium Okoume Marine Plywood may carry a higher initial price, its long-term benefits far outweigh the upfront cost. From durability and performance to reduced maintenance and improved safety, Okoume consistently proves to be the most cost-effective choice for marine projects.

If you’re building for longevity, efficiency, and peace of mind, premium Okoume isn’t an expense it’s an investment.

Frequently Asked Questions (FAQs)

- Is Okoume plywood suitable for saltwater environments?

Yes. Properly sealed Okoume Marine Plywood performs exceptionally well in saltwater conditions and resists moisture damage.

- Why do professionals prefer Okoume over other marine plywood?

Its lightweight strength, smooth finish, and long lifespan make Okoume Plywood ideal for high-performance marine applications.

- How long does premium Okoume plywood last?

With correct installation and sealing, premium Okoume can last 20–30 years or more in marine environments.

- Where should I buy authentic Okoume marine plywood?

Always source from certified Okoume Marine Plywood Suppliers or a trusted woodworking supplies store to ensure quality.

- Is Okoume plywood cost-effective for small marine projects?

Absolutely. Even for smaller builds, reduced maintenance and durability make Okoume a smart long-term choice.