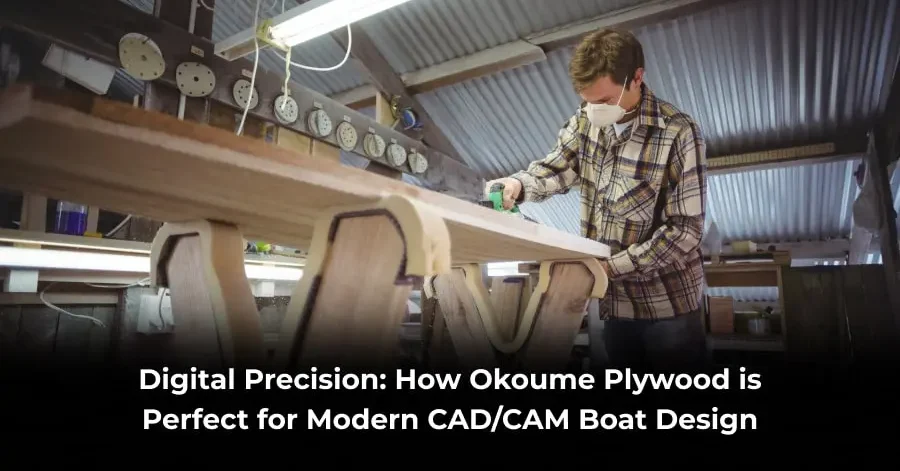

In the age-old craft of boatbuilding, a quiet revolution is underway. The scent of sawdust and the feel of a hand plane are now seamlessly blended with the hum of CNC routers and the glow of computer screens. This is the world of modern marine design, where CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) have become the standard. But for all the power of digital tools, they are only as good as the physical materials they shape. Enter an unsung hero: Okoume plywood.

This isn’t just any wood; it’s a material whose inherent properties align so perfectly with the demands of digital fabrication that it has become the substrate of choice for a new generation of builders. For anyone browsing a woodworking supplies store for a boat project, understanding the synergy between this specific marine plywood and modern technology is key to a successful build.

The Digital Blueprint: CAD’s Demand for Predictability

Before a single cut is made, a boat exists as a perfect, weightless model in a digital space. CAD software allows designers to push the boundaries of hull shape, weight distribution, and structural integrity. Every curve, every panel, and every structural member is meticulously calculated.

This digital precision demands a material that is equally predictable. You cannot feed a complex, multi-axis design into a computer and hope that a variable, inconsistent material will hold the shape. This is where okoume marine plywood shines. Its core characteristic, beyond its famous light weight, is its exceptional consistency.

- Uniform Core: Unlike some plywoods that can have voids or patches of inconsistent density, high-quality Okoume plywood is manufactured with a uniform, void-free core. For the CAD designer, this means the material behaves as a single, predictable entity. The software’s stress simulations and load calculations are accurate because the material’s properties are reliable from sheet to sheet.

- Stable Structure: The cross-laminated layers of marine-grade Okoume plywood provide dimensional stability, resisting warping and swelling far better than solid wood. When the CAD model specifies a 12mm thick panel, the builder can trust that the 12mm sheet of okoume marine plywood will maintain that thickness and flatness, ensuring a perfect fit.

In essence, CAD creates a perfect digital world, and Okoume plywood is one of the few materials that can faithfully manifest that perfection in the physical one.

The Robotic Craftsman: CAM’s Need for a Cooperative Material

Once the design is finalized, the CAM software takes over, translating the 3D model into a set of instructions for a CNC machine. This is where the theoretical meets the mechanical. The CNC router, a robotic craftsman, moves with inhuman speed and accuracy, but it is utterly reliant on the material it’s cutting.

Okoume plywood is the ideal partner for this process for several reasons:

- Machinability: The relatively soft nature of the Okoume wood (Aucoumea klaineana) means it is exceptionally easy to machine. It doesn’t blunt router bits quickly. It cuts cleanly, without excessive tear-out or chipping on the top and bottom layers. This results in a finished edge that often requires minimal sanding, saving countless hours in the workshop. When you source your materials from a reputable woodworking supplies store, you can be confident that the okoume marine plywood will run through your CNC without complaint.

- Perfect for Complex Cuts: Modern boat designs often feature complex, compound-curved panels that would be nearly impossible to lay out and cut by hand. A CNC machine can cut these shapes with ease, but the material must be able to handle sharp corners and intricate details without splintering. The fine, consistent grain of Okoume plywood allows for this precise, intricate cutting.

- Efficient Nesting: CAM software uses “nesting” algorithms to arrange all the parts from the boat design onto standard 4×8 or 8×8 sheets in the most material-efficient way possible. The consistent sheet size and quality of Okoume plywood make this nesting process highly efficient, minimizing waste and cost. You get more boat from every sheet.

The Human Touch: Why the Marriage Matters for Builders

You might wonder, in this high-tech process, where does the boatbuilder fit in? The answer is: right at the center, now empowered to do their best work.

The combination of CAD/CAM and Okoume plywood doesn’t eliminate craftsmanship; it elevates it. It removes the tedious, error-prone tasks of lofting (drawing full-sized plans) and manually cutting panels. This frees up the builder to focus on what truly requires a human touch: the fine joinery, the exquisite finishing, the art of fiberglassing, and the final assembly.

For the amateur builder sourcing from a local woodworking supplies store, this technology is a godsend. Many designers now sell “CNC-ready” kits for their plans. A builder can purchase the plans, send the digital files to a CNC cutting service (or cut them themselves if they have access to a machine), and receive a perfectly cut kit of parts in Okoume plywood. This dramatically lowers the barrier to entry for building a high-quality, professional-looking boat. It turns a years-long project into one that can be accomplished in a single season.

The Inherent Qualities of Okoume: More Than Just Digital Compatibility

While its performance in a digital workflow is paramount, we cannot overlook the traditional reasons why okoume marine plywood has been a favorite of boatbuilders for decades. These qualities are precisely why it was poised to become the material of choice for the digital age.

- Strength-to-Weight Ratio: This is Okoume’s superstar feature. It is incredibly light for its strength. A boat built from Okoume plywood will be lighter than one built from most other marine plywoods, leading to better performance, higher speeds, and better fuel efficiency.

- Marine-Grade Adhesives: Authentic okoume marine plywood uses waterproof phenolic resins, ensuring the layers remain bonded even in a perpetually wet environment.

- Beautiful Finish: With its warm, pinkish-brown hue and fine, straight grain, Okoume presents a beautiful surface. It takes epoxy and varnish exceptionally well, resulting in a finish that rivals the beauty of traditional hardwoods.

Sourcing Your Materials: The Importance of a Trusted Woodworking Supplies Store

Given the critical role material quality plays in a CAD/CAM project, where you source your Okoume plywood is not a decision to be taken lightly. Not all plywood labeled “marine” is created equal. You need a supplier that understands the specific needs of modern boatbuilding.

This is where partnering with a specialized woodworking supplies store makes all the difference. They will stock genuine, certified okoume marine plywood from reputable mills, ensuring the consistency and quality your project demands. The staff at a quality store will understand your project’s requirements and can provide invaluable advice on grades, thicknesses, and compatible epoxies and hardware.

Also Read- What is a Wood Grading System? The Ultimate Guide for Professionals

About AEW Woods

When seeking a supplier that embodies this standard of quality and expertise, look no further than AEW Woods. With a longstanding reputation for excellence, AEW Woods has established itself as a premier source for high-end woodworking and boatbuilding materials. They specialize in providing top-tier Okoume plywood and other marine-grade panels, understanding the precise demands of both professional shipyards and passionate amateur builders. Their commitment to quality ensures that every sheet of okoume marine plywood they supply meets the rigorous standards required for successful CAD/CAM construction, making them a trusted partner in bringing your digital designs to life.

Conclusion

The journey from a digital idea to a physical vessel is one of the most exciting evolutions in modern craftsmanship. In this process, Okoume plywood has proven to be more than just a material; it is a vital link between the binary world of ones and zeros and the tangible world of wood and water. Its consistency, machinability, and superb physical properties make it the perfect canvas for the digital precision of CAD/CAM.

So, whether you are a professional designer, a first-time builder ordering a kit, or simply an enthusiast browsing a woodworking supplies store, know that choosing okoume marine plywood is a decision that honors both the future and the past of boatbuilding. It is the material that allows the dreams of the digital designer to set sail, flawlessly formed and built to last.

Frequently Asked Questions (FAQs)

- Is Okoume plywood strong enough for a full-sized boat?

Absolutely. While it is lightweight, the cross-laminated construction of marine-grade Okoume plywood giFves it tremendous strength. When combined with proper epoxy fiberglass sheathing as part of a modern build, it creates an immensely strong and durable hull that is trusted by designers and builders worldwide for vessels up to and over 40 feet. - How does Okoume plywood compare to Meranti marine plywood?

Both are excellent marine plywoods. The primary difference is weight and hardness. Okoume plywood is significantly lighter and softer, making it superior for performance-oriented boats and easier to machine. Meranti is heavier and harder, often chosen for its dent resistance and slightly lower cost. For CNC-based builds, the machinability of Okoume plywood often makes it the preferred choice. - Can I use regular plywood from a home center for a CAD/CAM boat kit?

It is strongly discouraged. Regular construction plywood uses interior-grade adhesives that will fail when exposed to moisture, and the cores often have voids that create critical weak points. It also lacks the dimensional stability and consistent density required for the parts to fit together perfectly from a CNC cut. Always use certified marine-grade plywood like okoume marine plywood for any boatbuilding project. - Do I need a huge CNC machine to build with Okoume plywood?

Not necessarily. While large professional machines can cut entire 8×4 sheets, many successful small-boat builders use smaller, more affordable desktop or benchtop CNCs to cut smaller, more complex parts. Alternatively, you can purchase your Okoume plywood from a woodworking supplies store and use a CNC cutting service to have the parts pre-cut for you. - How do I protect and finish a boat made from Okoume plywood?

The modern standard is to sheath the hull in epoxy resin and fiberglass cloth. This creates a waterproof, incredibly strong, and durable shell that fully encapsulates the wood. After the epoxy work is complete, you can finish with a marine-grade paint or varnish to protect against UV rays and achieve the desired aesthetic.