Okoume plywood is a lightweight yet durable wood option favored by woodworkers, boat builders, and DIY enthusiasts. Known for its fine grain and excellent strength-to-weight ratio, Okoume marine plywood is widely used in marine applications, furniture making, and other specialized projects. Whether you’re a professional craftsman or a hobbyist, knowing how to cut and finish Okoume plywood correctly ensures a flawless outcome. This comprehensive guide walks you through the step-by-step process of handling, cutting, and finishing Okoume plywood while highlighting key factors such as Okoume marine plywood prices and sourcing from reliable lightweight plywood suppliers.

Understanding Okoume Plywood

Before diving into the cutting and finishing process, it’s essential to understand what makes Okoume plywood unique. Okoume is a tropical hardwood species native to Africa and is renowned for its smooth surface, light weight, and resistance to moisture. This makes Okoume marine plywood an excellent choice for boat building, cabinetry, and interior paneling.

Why Choose Okoume Plywood?

- Lightweight: Compared to other plywood types, Okoume is significantly lighter, making it easy to handle and ideal for marine and aviation applications.

- Aesthetic Appeal: It’s fine grain and smooth surface make it a top choice for high-end furniture and decorative paneling.

- Durability: Marine-grade Okoume plywood is treated to resist water damage, fungi, and decay.

- Workability: It is easy to cut, sand, and finish, allowing for a professional look with minimal effort.

Step 1: Selecting Quality Okoume Plywood

Choosing the right Okoume plywood is the first step in achieving a superior finish. When purchasing, consider:

- Thickness & Grade: Depending on your project, select the appropriate thickness (commonly 3mm to 18mm) and grade (A-A, A-B, etc.).

- Supplier Reputation: Purchase from reliable Okoume marine plywood suppliers to ensure high-quality material.

- Cost Considerations: Compare Okoume marine plywood prices among different lightweight plywood suppliers to get the best deal.

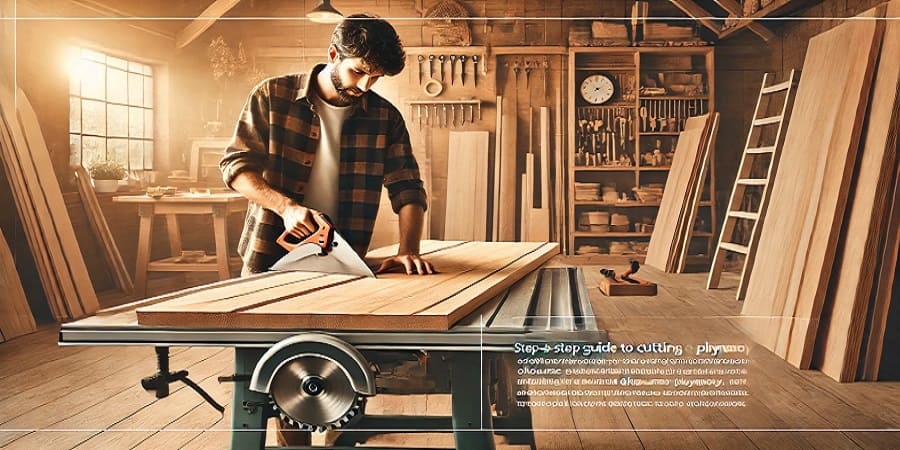

Step 2: Preparing for Cutting

Tools Needed:

- Circular saw or table saw (for straight cuts)

- Jigsaw (for curved or intricate cuts)

- Clamps

- Measuring tape

- Pencil or chalk for marking

- Safety glasses and dust mask

Marking the Cut Lines:

- Measure and mark the cutting lines with a pencil or chalk.

- Use a straightedge or ruler to ensure precision.

- Double-check measurements to avoid material waste.

Step 3: Cutting Okoume Plywood

Straight Cuts:

- Use a circular saw or table saw with a fine-toothed blade to minimize splintering.

- Clamp the plywood securely to prevent shifting.

- Cut at a slow, steady pace to achieve clean edges.

Curved Cuts:

- A jigsaw with a fine blade is ideal for intricate or curved cuts.

- Work slowly and follow the marked lines carefully to maintain accuracy.

- If necessary, use a guide or template for complex shapes.

Tips for Reducing Tear-Out:

- Apply painter’s tape over the cut line before cutting.

- Use a sharp, high-quality blade.

- Cut with the finished side facing down when using a circular saw.

Step 4: Sanding the Edges and Surface

Sanding is crucial to achieving a smooth and polished finish. Follow these steps:

- Use 120-grit sandpaper for initial sanding to remove rough edges.

- Progress to 220-grit sandpaper for a finer finish.

- Sand along the grain to maintain the plywood’s natural appearance.

- Wipe the surface with a tack cloth to remove dust.

Step 5: Sealing and Finishing

To enhance durability and aesthetics, Okoume plywood should be sealed and finished properly.

Applying Sealant:

- Marine-grade Okoume plywood requires sealing to protect against moisture.

- Apply a clear epoxy resin or wood sealer using a brush or roller.

- Allow adequate drying time before proceeding to the next step.

Staining or Painting:

- If you prefer a natural look, apply a wood stain that complements the grain.

- For a painted finish, use high-quality marine paint for added protection.

- Apply multiple thin coats, allowing each coat to dry before adding another.

Final Protective Coating:

- Apply a polyurethane or marine varnish for added durability.

- Sand lightly between coats for a professional-grade finish.

- Let the plywood cure fully before using it in any project.

Step 6: Maintaining Okoume Plywood

Proper maintenance extends the lifespan of Okoume plywood. Follow these maintenance tips:

- Keep the surface clean and dry to prevent moisture damage.

- Reapply sealant or varnish periodically for added protection.

- Store plywood in a dry, well-ventilated area when not in use.

Final Thoughts

Okoume plywood is an excellent choice for a variety of woodworking projects, offering both beauty and resilience. By following this step-by-step guide, you can ensure clean cuts, smooth finishes, and long-lasting results. Whether you’re sourcing from Okoume marine plywood suppliers or looking for the best Okoume marine plywood prices, investing in quality materials and proper finishing techniques will yield outstanding outcomes. With careful handling, cutting, and finishing, your Okoume plywood projects will stand the test of time while maintaining their elegance and durability.