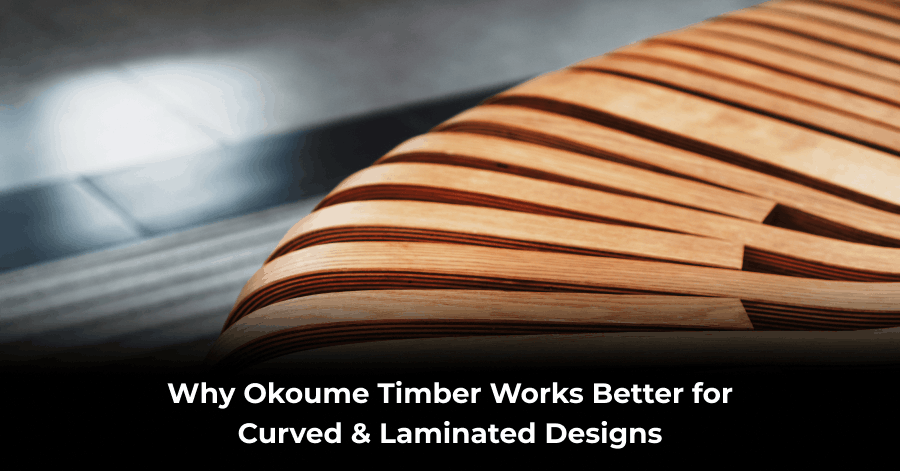

Curves tell stories. From flowing yacht interiors and elegant furniture profiles to architectural panels that feel alive, curved and laminated designs bring warmth and sophistication that flat boards simply can’t match. But here’s the catch not all wood is made to bend without breaking.

This is where okoume wood quietly outperforms many traditional timbers.

Favored by designers, boat builders, and manufacturers across the globe especially in West Africa okoume plywood and okoume marine plywood have become the go-to materials for smooth curves, tight laminations, and long-lasting performance. In this blog, we’ll break down why okoume timber works so well for curved and laminated designs, how it compares to other options, and why sourcing it from trusted hardwood timber suppliers in Gabon makes all the difference.

Understanding Curved & Laminated Wood Design

Before diving into okoume specifically, let’s understand what curved and laminated designs demand from timber.

Curved and laminated applications require wood that can:

- Bend without cracking

- Maintain consistent grain

- Bond well with adhesives

- Retain strength after shaping

- Stay dimensionally stable over time

Many hardwoods struggle here. Dense or brittle woods resist bending, develop stress fractures, or delaminate under pressure. Okoume wood, on the other hand, is naturally suited to this process.

What Makes Okoume Wood Unique?

Okoume is a lightweight hardwood species native to Central and West Africa, particularly Gabon. It has a fine, uniform grain, a smooth texture, and a pale pinkish-brown appearance that finishes beautifully.

What truly sets okoume apart is its excellent strength-to-weight ratio, making it flexible without being weak an ideal combination for curved forms.

This is why woodworking supplies stores in Gabon often recommend okoume timber for advanced design applications, especially where aesthetics and performance must coexist.

Why Okoume Timber Excels in Curved Designs

1. Superior Flexibility Without Structural Failure

One of the biggest advantages of okoume wood is its ability to bend gradually and evenly. When steamed or laminated in thin layers, okoume conforms to curves without splintering or tearing along the grain.

This makes it perfect for:

- Curved furniture frames

- Rounded cabinetry

- Boat hulls and interiors

- Architectural wall panels

Unlike heavier hardwoods, okoume doesn’t “fight back” during shaping, which saves both material and labor.

2. Consistent Grain for Smooth Laminations

Laminated designs rely on multiple thin layers bonding together flawlessly. Any inconsistency in grain can cause weak points.

Okoume plywood is known for its:

- Straight grain pattern

- Minimal knots

- Uniform veneer thickness

These characteristics allow layers to align cleanly, resulting in stronger, more predictable laminations a key reason okoume marine plywood is widely used in marine and high-stress environments.

3. Lightweight Nature Reduces Stress on Curves

Weight matters more than most people realize.

Heavy timber puts internal stress on curved joints over time, increasing the risk of deformation or delamination. Okoume’s lightweight structure significantly reduces this issue.

This is why okoume marine plywood is extensively used in:

- Yacht interiors

- Boat decks

- Curved marine furniture

It maintains its form while keeping the overall structure light and balanced.

4. Excellent Adhesive Bonding

Curved and laminated designs depend heavily on adhesive strength.

Okoume wood has a smooth, even surface that:

- Absorbs adhesives uniformly

- Forms strong glue lines

- Minimizes bonding failures

Whether you’re using it in interior furniture or marine-grade applications, okoume plywood ensures long-term durability when laminated properly.

Why Okoume Marine Plywood Is a Game-Changer

When moisture resistance enters the equation, okoume marine plywood becomes the preferred choice.

Manufactured using waterproof adhesives and high-quality okoume veneers, it offers:

- Resistance to humidity and water exposure

- Dimensional stability in changing climates

- Long lifespan in demanding environments

For curved designs in coastal architecture, marine interiors, or humid regions, this type of plywood outperforms many alternatives.

Okoume vs Other Hardwoods for Curved Work

| Feature | Okoume Wood | Traditional Hardwoods |

| Flexibility | Excellent | Moderate to poor |

| Weight | Lightweight | Heavy |

| Grain Consistency | High | Varies |

| Laminating Ease | Very easy | Often difficult |

| Marine Use | Ideal | Limited |

This comparison explains why many hardwood timber suppliers increasingly recommend okoume for modern curved and laminated designs.

Sustainability & Responsible Sourcing in Gabon

Another key reason designers choose okoume is sustainability when sourced responsibly.

Gabon is one of the world’s leading producers of okoume timber, with strict forestry regulations and controlled harvesting. Trusted woodworking supplies stores in Gabon and certified suppliers ensure:

- Legal logging practices

- Reforestation initiatives

- FSC-compliant supply chains

For global buyers, sourcing from reliable hardwood timber suppliers in Gabon ensures both quality and environmental responsibility.

Design Applications Where Okoume Shines

Okoume plywood and okoume marine plywood are widely used in:

- Curved furniture and designer seating

- Luxury yacht interiors

- Decorative wall cladding

- Architectural panels

- Custom cabinetry

- Laminated doors and frames

Its versatility allows architects and designers to push creative boundaries without compromising strength.

Why Designers & Manufacturers Prefer Okoume

In real-world projects, okoume wood delivers:

- Faster fabrication

- Lower material wastage

- Cleaner finishes

- Long-term structural reliability

That’s why it’s becoming a favorite among both boutique designers and large-scale manufacturers.

Why AEW Woods Is a Trusted Name for Okoume Timber

When it comes to sourcing premium okoume wood, AEW Woods stands out as a reliable partner.

With deep expertise in African hardwoods, AEW Woods works closely with certified forestry operations and leading hardwood timber suppliers in Gabon. They provide:

- High-quality okoume plywood

- Marine-grade okoume marine plywood

- Consistent grading and moisture control

- Global export support

Whether you’re a furniture manufacturer, marine builder, or architect, AEW Woods ensures dependable supply without compromising on quality or sustainability.

Conclusion

Curved and laminated designs demand more from timber and okoume wood consistently delivers. Its natural flexibility, uniform grain, lightweight structure, and superior bonding properties make it one of the best materials for modern woodworking and architectural applications.

From elegant furniture curves to durable marine interiors, okoume plywood and okoume marine plywood offer a rare balance of beauty and performance. When sourced responsibly from trusted woodworking supplies stores in Gabon and experienced hardwood timber suppliers like AEW Woods, okoume becomes not just a material but a design advantage.

Frequently Asked Questions:

- Why is okoume wood better for curved designs?

Okoume wood bends easily without cracking due to its fine grain and lightweight structure, making it ideal for curved and laminated applications.

- Is okoume marine plywood suitable for humid environments?

Yes, okoume marine plywood uses waterproof adhesives and is designed to perform well in moisture-rich and marine conditions.

- Can okoume plywood be used for furniture?

Absolutely. Okoume plywood is widely used for curved furniture, cabinetry, and decorative panels due to its smooth finish and flexibility.

- Where is the best source for okoume wood?

Gabon is one of the most reliable sources of premium okoume wood, supplied by certified hardwood timber suppliers and woodworking supplies stores in Gabon.

- Why choose AEW Woods for okoume timber?

AEW Woods offers high-quality, responsibly sourced okoume plywood and okoume marine plywood with consistent grading, making them a trusted global supplier.