When a plywood sheet is labeled “marine g…

Why Cheap Okoume Plywood Fails Early (Real-World Examples)

At first glance, cheap Okoume plywood loo…

How to Verify Okoume Marine Plywood Before Purchase: A Buyer’s Test Guide

Buying okoume marine plywood isn’t just a…

Calculating Your Needs: How Much Okoume Timber Do You Really Need for a Kayak?

Building a kayak with your own hands is o…

The Truth About Okoume Wood Finishing: Best Practices for a Flawless, Lasting Coat

When woodworkers talk about beautiful fin…

Beyond Price: 3 Often-Overlooked Factors When Choosing a Woodworking Supplies Store

When sourcing materials for woodworking, …

Okoume vs. Sapele for Marine Applications: A Cost, Weight, and Durability Deep Dive

Marine engineering, boatbuilding, and hig…

Beyond FSC: Understanding Blockchain Timber Tracking for Your Okoume Wood Supply

For decades, the forestry sector has reli…

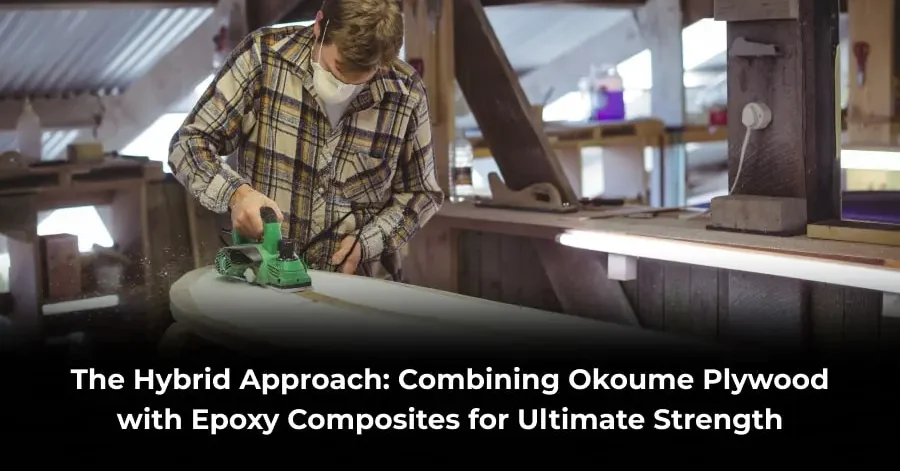

The Hybrid Approach: Combining Okoume Plywood with Epoxy Composites for Ultimate Strength

When it comes to building high-performanc…

The Art of the Float: Building a Stand-Up Paddleboard (SUP) with Okoume Marine Plywood

Stand-up paddleboarding (SUP) has grown i…